Simulation Analysis and Optimum Design of Vibration Reduction Effect of Auxiliary Car Stretcher

Simulation Analysis and Optimization Design of Vibration Reduction Effect

Based on the theory of multi-body system dynamics, the simulation model of ambulance system is established in ADAMS software. The model includes wheel (4), vehicle body, equivalent suspension, stretcher bracket, And the suspension parameters are obtained by the parameter identification method based on the genetic algorithm. The first stage wire rope spring is used to simulate the sleeve force Bushing, and the second grade wire rope spring is simulated by the vertical single force force SForce. The model signal is stimulated in the time domain by the shaft signal measured at the time of traveling with the car.

According to the original car program to set the parameters, the obtained under the bracket vibration acceleration simulation and test comparison shown in Figure, can be seen from the figure, the simulation and test results in line with the better.

Aiming at the damping effect of four schemes under the excitation of gravel road conditions, the simulation analysis and optimization design are carried out.

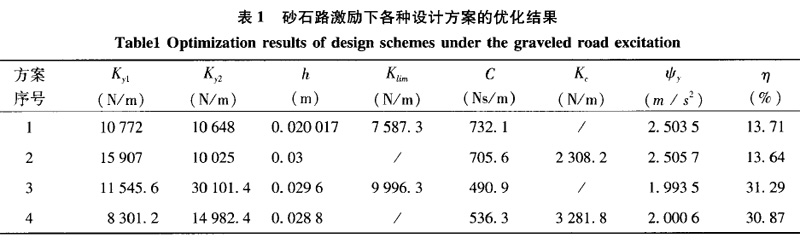

(X1, z2), (x3, z3), (x4, z4), (x5, z2), (x2, z2), (x3, z2), (x4, z2) (X6, z6), (x7, z7); the vertical stiffness of the secondary wire rope K2, the position coordinates x8, x9, x10, x11; the height difference of the two-stage wire rope h, the damping coefficient of the damper (single) , Limit spring stiffness K (damper springback stiffness Kc). The objective function is the acceleration root mean square value of the vertical vibration of the human body center of the stent. The results of the optimized design are shown in Table 1.

It can be seen from the optimization results of the above four schemes: It is better to install the two-stage wire rope damper in the four-legged bracket of the stretcher bracket, especially in the case of the installation of four elastic limit springs (Option 3) .

Conclusion

In this paper, the design of the two-stage wire rope combination damping program, the use of high and low combination of wire rope spring, by increasing the damping energy-consuming components, improve the limit device to optimize the structure of wire rope spring, physical parameters and installation, not only inherited the wire rope Low vibration efficiency, reliable performance and convenient maintenance, and the overall vibration intensity of the stretcher support system is obviously reduced, and the vibration reduction efficiency is 31.29%.

Official WeChat

Official WeChat