Research on Parametric Design of Stretcher Bed

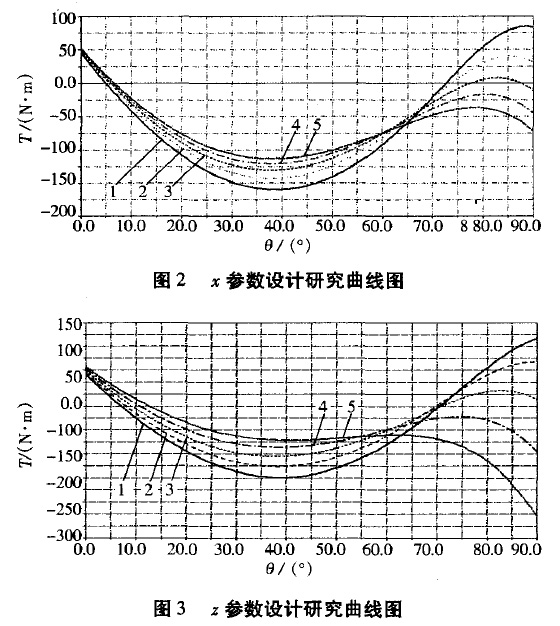

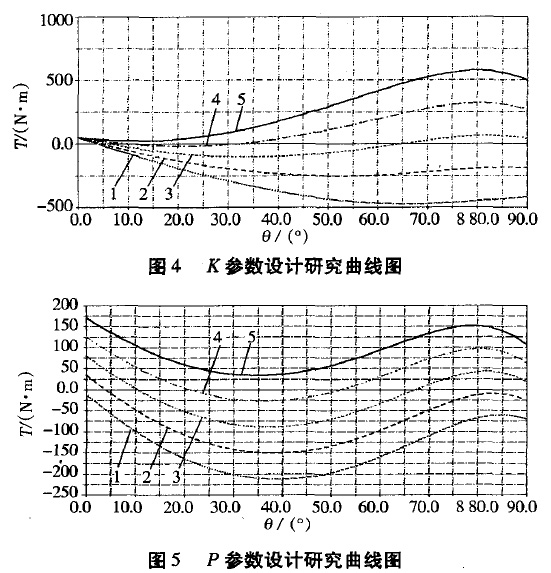

In the ADAMS \ Design Design (Design Study), the design variables in accordance with certain rules in a certain range of values. According to the design variable value, a series of simulation. After completing the design simulation study, the results of each simulation analysis are output. In the following, we will use the parameters of x, z, K and P as the parameters, and the parameters of the previous bearing are designed. The simulation results show that the design parameters of the design variables take a series of different values, The change curve of the connecting rod angle is shown in Fig. 2 and Fig. 5, where θ is the front connecting rod angle and T is the driving torque.

In Figure 2, curves 1-5 correspond to variables x = 550 mm, 600 mm, 650 mm, 700 mm, 750 mm, respectively. In Figure 3, curves 1 to 5 correspond to variables z = -100 mm, -50 mm, 0 mm, 50 mm, 100 mm, respectively. In Fig. 4, curves 1 to 5 correspond to variables K = 0 N / mm, 5 N / mm, 10 N / mm, 15 N / mm, 20 N / mm, respectively. In Fig. 5, curves 1-5 correspond to variables P = 0 N, 250 N, 500 N, 750 N, and 1000 N, respectively.

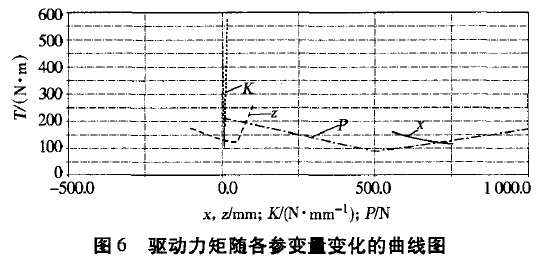

Figure 6 is a simulation of the process of driving torque changes with the parameters of the curve. As can be seen from Fig. 6, the z-axis coordinates of the spring and the spring stiffness K are the main influence on the design variables, and their changes have a great influence on the performance of the prototype.

Official WeChat

Official WeChat